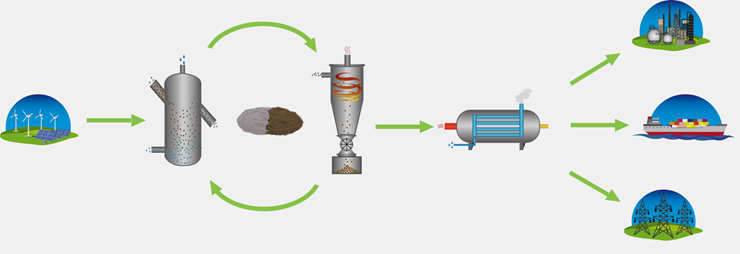

Sustainable energy is – by using the produced sustainable hydrogen amongst other things – used for the reduction of rust powder (Fe203) to iron powder (Fe). Iron powder can be used as a fuel for largescale transport, to generate (high-temperature) (process)-warmth and electricity. Iron powder is somewhat heavier than other energy carriers, but very compact, safer and cheaper than the storage of energy via hydrogen, CO2 free and circular. On top of that it promises that the emissions of other substances (NOx and particulate matter) will be very limited.

We are on the verge of a global energy transition, of which the start is hindered by two big challenges:

At this moment there is significantly invested in hydrogen as energy carrier. In many cases this is the most suitable solution: largescale storage of hydrogen is relatively difficult because of the security demands and the fact that it needs a lot of space. Salt caverns offer solutions, however they can’t be found everywhere in the Netherlands and are limited in size. Iron powder is a great alternative because it’s compact, safe, and cheaper to store and transport.

These characteristics make iron fuel interesting as a long-term storage medium for the industry and warmth production (1-10 MW). Especially where hydrogen (transport network, big tank or cavern) is or will be available and where the safety concerning storage is more difficult to guarantee (for example in the inner cities).

The usage of iron dust has great potential for the largescale import of sustainable energy from countries where energy can be produced cheap (with a lot of sun/wind around the equator). According to Metalot this option will arise in the near future when it turns out that the Netherlands (and Europe) will discover that locally insufficient sustainable energy can be produced to provide the whole community including the industry of enough sustainable energy.

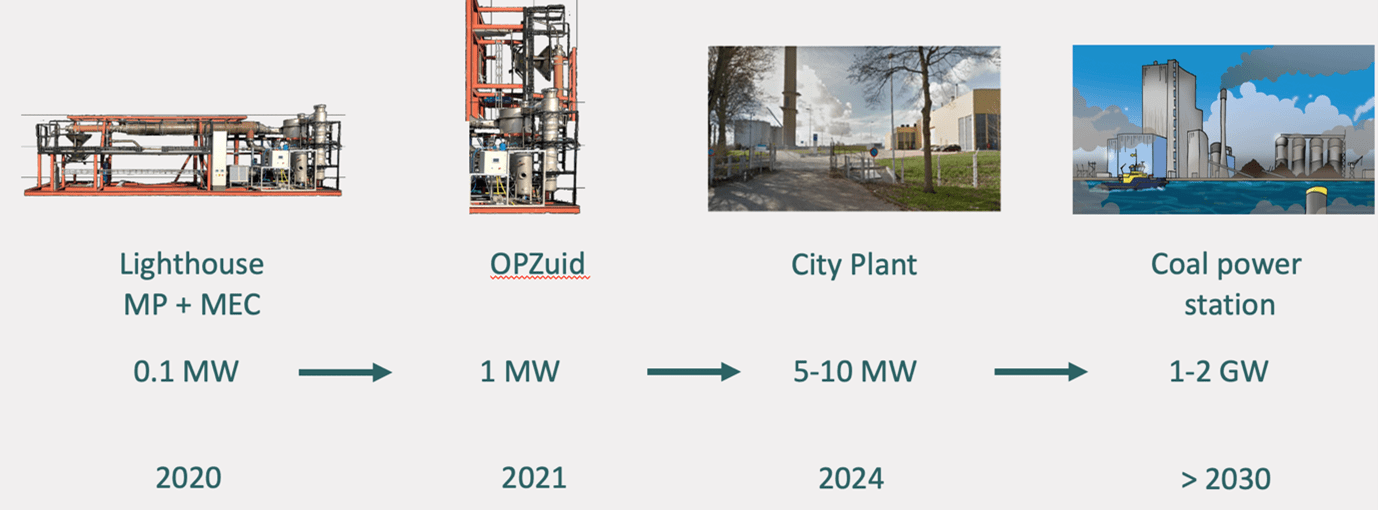

The goal of Metalot Metal Power community is to realize, scale up and prepare the technology and the market concerning metal fuels for the market. The first step is MP100, a 100 KW system with which process warmth can be produced, as seen in the attached image.

Metalot communityTogether with the consortium of parties which cover the whole value chain, technical-economical studies and market studies are executed and technological/financial roadmaps are developed. It is a collaboration with parties who are responsible for the iron powder production up and including to parties who take care of the energy-production and industrial processes.

Within the borders of these roadmaps new technological steps are taken with the goal to develop industrial systems of 1-10 MW and finally to build complete coal-fired power stations (after 2030). Intellectual property is being developed and licensed by the consortium in an open innovation context to license this jointly and establish spin-offs. The main envisaged steps are shown in the figure below.